Chemical Process Engineering

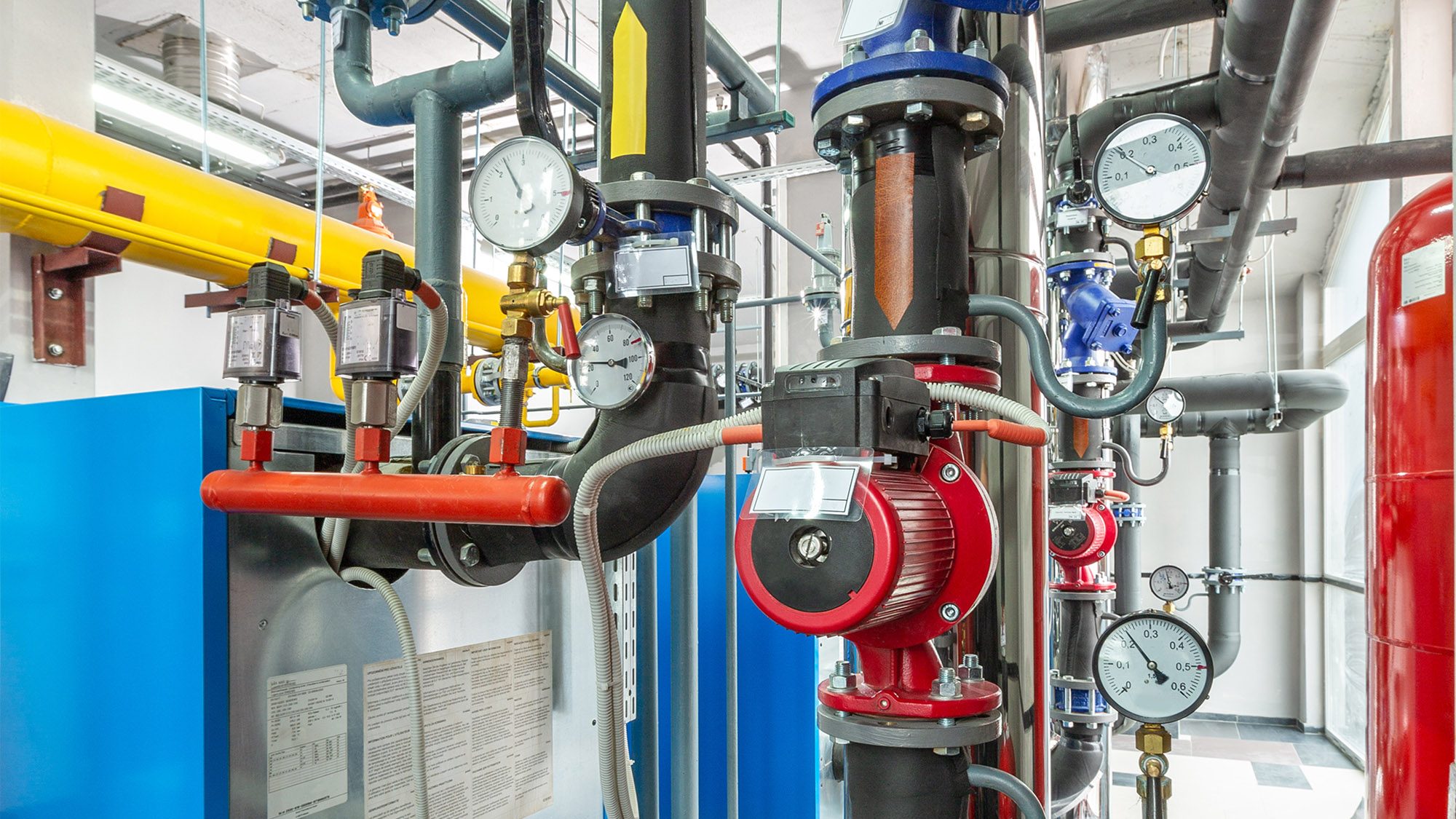

AED’s Chemical Process Engineering Department is the tip of the spear for all projects. We emphasize the importance of focusing our attention on the initial point of contact with the client as this sets the tone for the entirety of the project and its mission success. Our team helps translate concepts into the feasibility and then the reality of their vision. Our experienced and skilled engineers rely on their analysis, calculations, and modeling to ensure consistency and integrity of the materials being processed from beginning to end. P&ID development throughout the project lifecycle is critical to preserving the functionality of the process flow and all disciplines supporting those efforts.

Capabilities

PFD / P&ID Development

PHA / HAZOP / LOPA

SIS Development

Hydraulic Studies

Dispersion Modeling

Process Simulation

Process Sizing and Specification of Equipment

Process Design

Basis of Design

Energy Studies

PSV Studies

Technology

Feasibility is the launch point for all process-driven designs. To provide our clients with the best solution to improve their operations and safeguard their materials and production output, our engineers work with Unisim and proprietary programs. These applications improve efficiency and help enhance quality control.

Projects

How is Allied Different?

“What I enjoy most about working at Allied is the opportunity to work with and develop young engineers. Our team communicates well. This empowers us to efficiently execute process engineering tasks that help our clients improve their plant efficiency, grow their facilities, and de-bottleneck their processes.”

Chris Singley | Process Department Manager