Piping systems are the arteries of industrial facilities, carrying critical fluids and gases throughout complex networks. Ensuring these systems are reliable, safe, and efficient requires more than basic design. It requires a deep understanding of how pipes respond to thermal expansion, internal pressure, and external forces. Pipe Stress Analysis (PSA) allows engineers to identify high-stress points, optimize support placement, allow areas of pipe movement, and prevent failures before they occur.

Understanding Pipe Stress and Its Impact

Pipe Stress Analysis evaluates how piping systems behave under various operational conditions. It accounts for temperature changes, internal pressure, and external loads. Without proper analysis, even minor oversights can lead to fatigue, leaks, or catastrophic failures. PSA provides engineers with a roadmap to design piping that can withstand real-world challenges while balancing safety, performance, and cost efficiency.

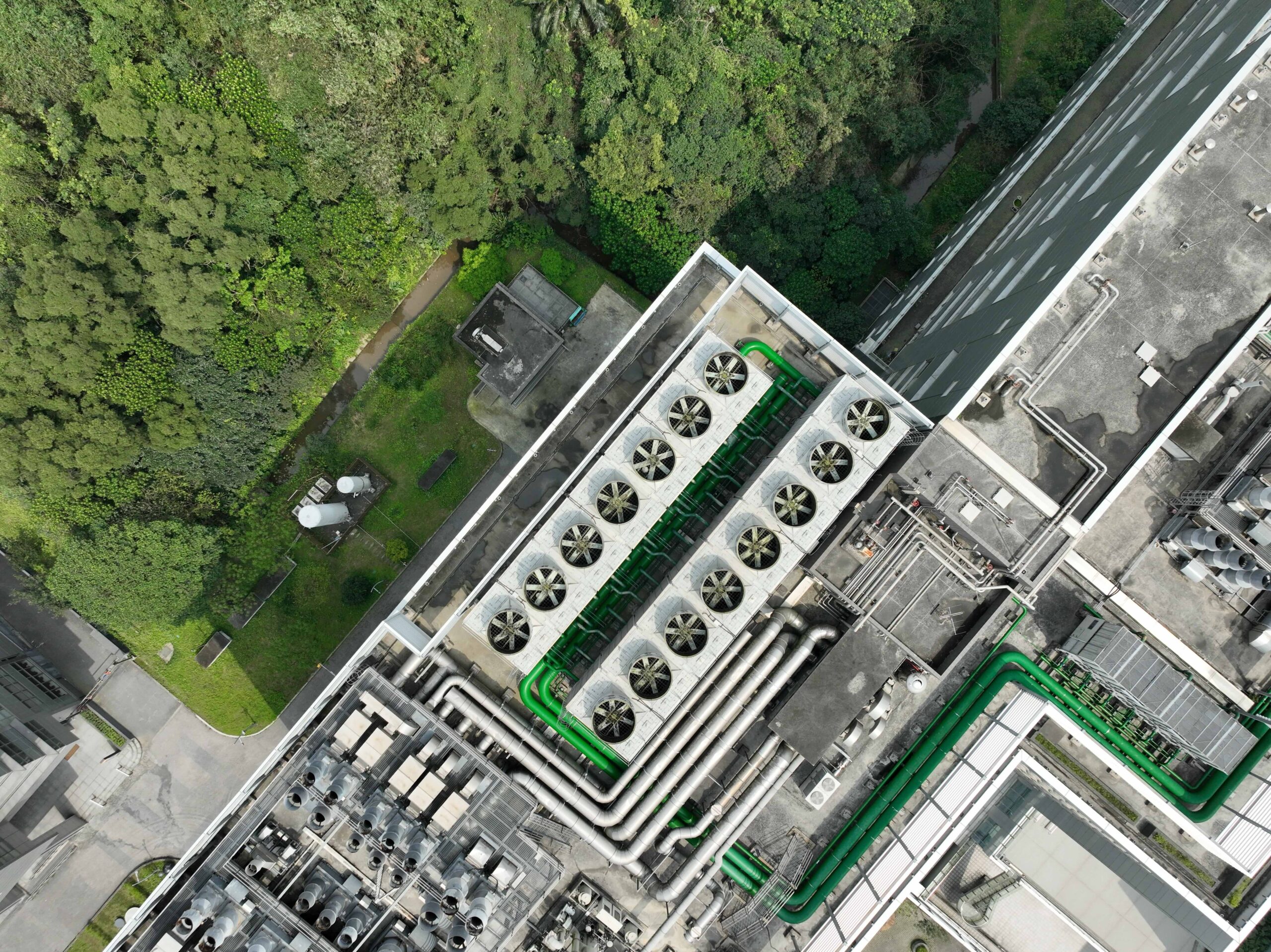

Pipe Stress Analysis Applied to Heat Exchanger Installations

A recent refinery project illustrates the value of Pipe Stress Analysis in practice. AED provides FEED and detailed design services for a new heat exchanger installation. This included civil and structural designs for the foundation, instrumentation and controls design, and all associated piping systems.

Pipe Stress Analysis was applied to the additional piping required for the installation. By modeling how the piping would react under thermal expansion, internal pressure, and external forces, the engineering team determined optimal support locations, support types, selected appropriate materials, and confirmed the layout would operate safely alongside the new heat exchanger. The result was a fully integrated system that met safety standards, minimized the risk of failure, and maintained operational continuity.

The Advantages of Pipe Stress Analysis for Industrial Projects

Applying PSA provides measurable benefits for industrial projects. It reduces the risk of downtime caused by leaks or failures, avoids overdesign, and ensures equipment performs reliably under both expected and unexpected conditions. For installations like heat exchangers, PSA also facilitates smooth integration with existing systems, prevents costly rework, and supports uninterrupted operations.

Designing Piping Systems for Reliability and Safety

Pipe Stress Analysis is more than a technical step. It is a proactive approach to building piping systems that are reliable, safe, and efficient. By identifying and addressing stress points early, engineers can design piping that supports complex equipment, accommodates operational demands, and protects facilities from disruption. PSA turns theoretical analysis into practical solutions that keep industrial operations running smoothly.